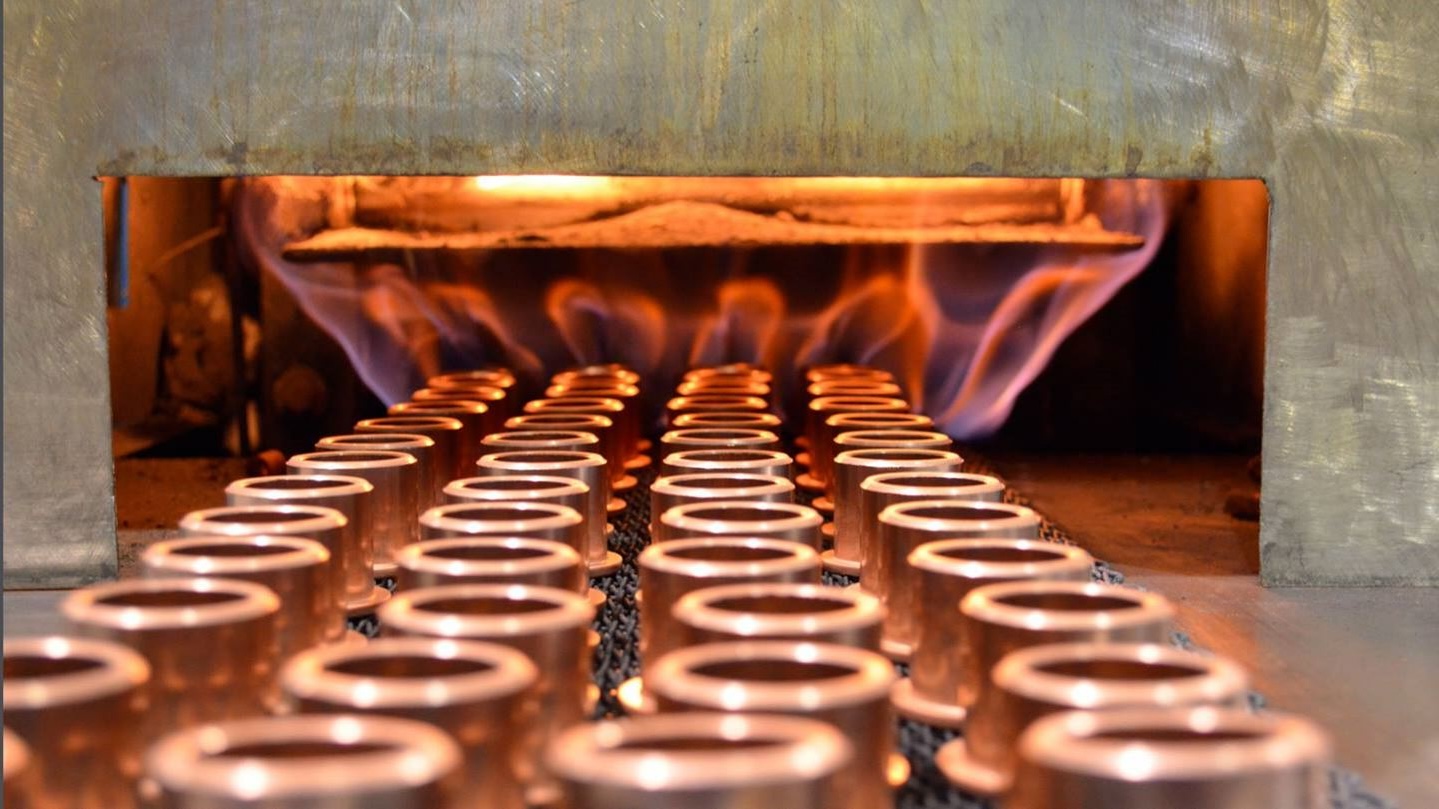

Sintering is a process that transforms powdered materials into solid structures by heating them below their melting points. This technique is crucial in manufacturing ceramics, metals, and plastics. But why is sintering so important? Sintering enhances the strength, durability, and thermal conductivity of materials, making them ideal for various applications, from aerospace components to dental implants. The process involves three stages: initial bonding, intermediate densification, and final densification. Each stage plays a vital role in achieving the desired material properties. Curious about how this works? Let's dive into 34 fascinating facts about sintering that will shed light on its significance and applications.

What is Sintering?

Sintering is a fascinating process used in manufacturing to create solid materials from powders. By heating the powder below its melting point, particles bond together, forming a solid piece. This technique is crucial in various industries, from ceramics to metallurgy. Let's dive into some intriguing facts about sintering.

-

Ancient Origins: Sintering dates back to ancient civilizations. Early humans used this technique to create pottery and bricks.

-

Temperature Control: The process requires precise temperature control. Too high, and the material melts; too low, and the particles won't bond.

-

Powder Variety: Almost any material that can be powdered can be sintered, including metals, ceramics, and plastics.

-

Porosity: Sintered materials often have tiny pores, making them useful for filters and other applications requiring permeability.

-

Strength Enhancement: Sintering can significantly enhance the strength of a material compared to its powdered form.

Applications of Sintering

Sintering isn't just a lab experiment; it's a vital part of many industries. From automotive to aerospace, this process has numerous applications.

-

Automotive Industry: Many car parts, like gears and bearings, are made using sintering due to its ability to produce strong, durable components.

-

Aerospace: Lightweight, high-strength materials created through sintering are essential for aircraft and spacecraft.

-

Medical Implants: Sintered materials are used to make biocompatible implants, such as dental crowns and bone replacements.

-

Electronics: The process is used to create components like capacitors and resistors, which are essential for electronic devices.

-

Jewelry: Some high-end jewelry pieces are made using sintered metals, allowing for intricate designs and strong structures.

Types of Sintering

There are several types of sintering, each with its unique characteristics and applications. Understanding these can help in choosing the right method for a specific need.

-

Solid-State Sintering: This is the most common type, where the powder is heated below its melting point.

-

Liquid-Phase Sintering: Involves adding a small amount of liquid to the powder, which helps in bonding the particles more effectively.

-

Pressure-Assisted Sintering: Applying pressure during the process can enhance the bonding and reduce porosity.

-

Spark Plasma Sintering: Uses electrical discharges to heat the powder, allowing for rapid sintering at lower temperatures.

-

Microwave Sintering: Uses microwave energy to heat the powder, offering faster processing times and energy savings.

Benefits of Sintering

Sintering offers numerous advantages over other manufacturing processes. These benefits make it a preferred choice in many applications.

-

Material Efficiency: The process uses almost all the material, resulting in minimal waste.

-

Cost-Effective: Lower energy consumption and material waste make sintering a cost-effective manufacturing method.

-

Complex Shapes: It allows for the creation of complex shapes that would be difficult or impossible to achieve with other methods.

-

Consistency: Sintering provides consistent material properties, essential for high-performance applications.

-

Customization: The process can be tailored to produce materials with specific properties, such as hardness or porosity.

Challenges in Sintering

Despite its many benefits, sintering also comes with challenges. Addressing these can help improve the process and its outcomes.

-

Temperature Control: Maintaining the precise temperature required can be challenging and requires sophisticated equipment.

-

Material Selection: Not all materials are suitable for sintering, and choosing the right powder is crucial.

-

Porosity Issues: While porosity can be beneficial, it can also weaken the material if not controlled properly.

-

Equipment Costs: The specialized equipment needed for sintering can be expensive, making it less accessible for small-scale operations.

-

Process Time: Sintering can be time-consuming, especially for large or complex parts.

Innovations in Sintering

The field of sintering is constantly evolving, with new innovations making the process more efficient and versatile.

-

Additive Manufacturing: Combining sintering with 3D printing allows for the creation of complex, high-strength parts.

-

Nanoparticle Sintering: Using nanoparticles can reduce sintering temperatures and improve material properties.

-

Hybrid Sintering: Combining different sintering methods, such as microwave and pressure-assisted, can enhance the process.

-

Advanced Materials: New materials, such as high-entropy alloys, are being developed specifically for sintering.

-

Sustainable Sintering: Efforts are being made to make the process more environmentally friendly, such as using renewable energy sources.

Future of Sintering

The future of sintering looks promising, with ongoing research and development paving the way for new applications and improvements.

-

Bioprinting: Sintering could play a role in bioprinting, creating complex tissue structures for medical use.

-

Space Exploration: Sintered materials could be used to build structures on other planets, utilizing local resources.

-

Energy Storage: Advanced sintered materials could improve the efficiency of batteries and other energy storage devices.

-

Smart Materials: The development of smart materials that can change properties in response to external stimuli could revolutionize various industries.

The Final Word on Sintering

Sintering is a fascinating process that transforms powdered materials into solid objects using heat. This technique is crucial in industries like ceramics, metallurgy, and additive manufacturing. By understanding the basics of sintering, you can appreciate how everyday items, from car parts to dental implants, are made.

The process involves heating materials just below their melting point, causing particles to bond without liquefying. This results in strong, durable products with unique properties. Sintering also allows for complex shapes and high precision, making it invaluable in modern manufacturing.

Whether you're a student, a hobbyist, or someone curious about how things are made, knowing about sintering adds a layer of appreciation for the technology behind many products. Keep exploring and stay curious—there's always more to learn about the world around us.

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.