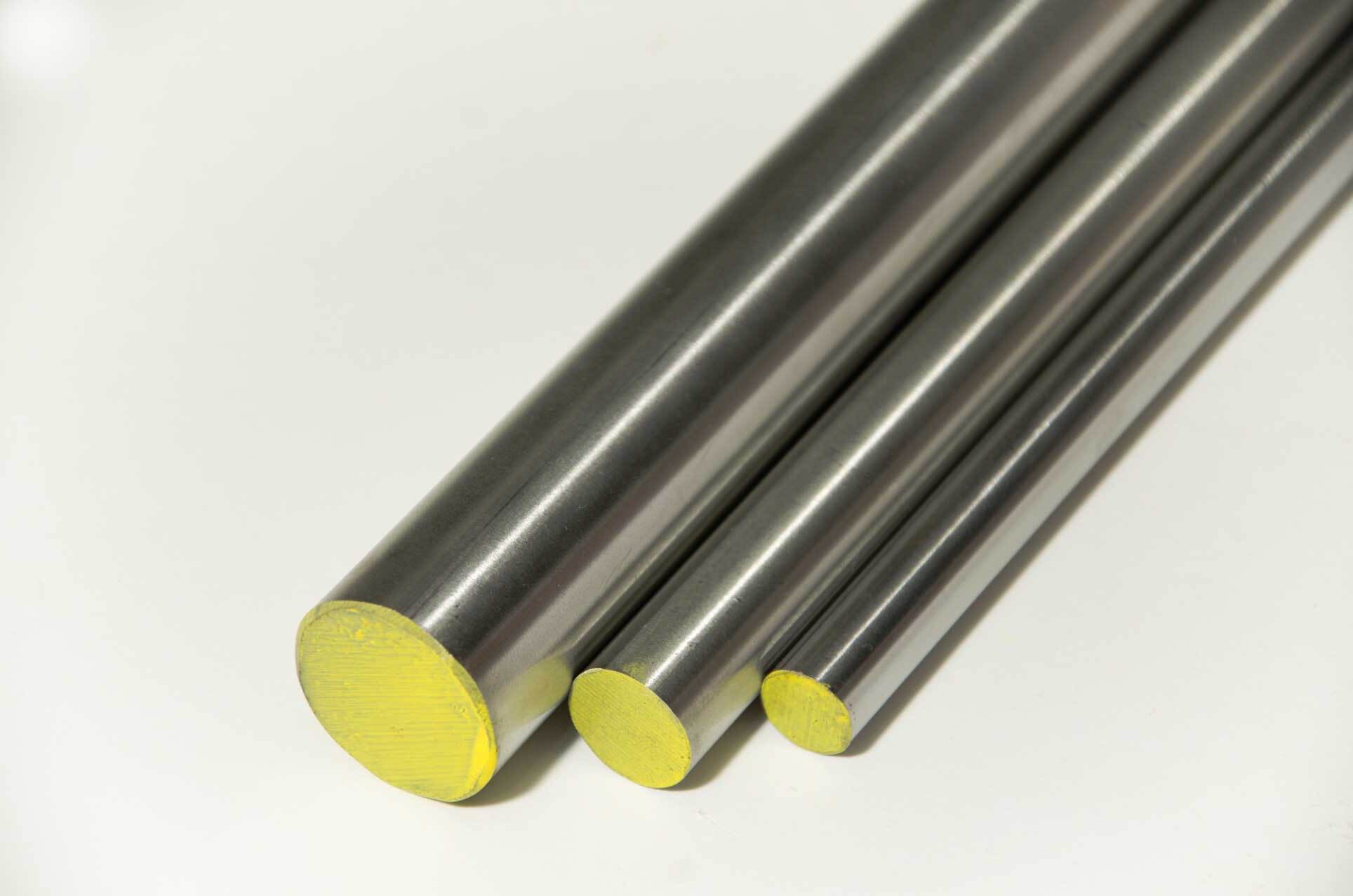

What makes silver steel (drill rod) so special? This versatile material, known for its high carbon content, is a favorite among machinists and toolmakers. Silver steel stands out due to its exceptional hardness, strength, and ability to be easily machined. It's often used in the creation of precision tools, such as drill bits, reamers, and punches. This steel's unique composition allows it to be hardened through heat treatment, making it incredibly durable. Whether you're crafting intricate components or heavy-duty tools, silver steel offers reliability and performance. Ready to learn more? Let's dive into 25 fascinating facts about this remarkable material!

Key Takeaways:

- Silver steel, also known as drill rod, is a high-carbon tool steel with excellent machinability and hardening capabilities. It is used for making durable tools and components in various industries.

- With its high carbon content, silver steel can achieve a hardness of up to 64 HRC, making it suitable for high-stress applications. Its versatility and wear resistance make it a valuable material in manufacturing and engineering.

What is Silver Steel?

Silver steel, also known as drill rod, is a versatile and high-carbon tool steel. It is known for its excellent machinability and ability to be hardened. Here are some interesting facts about this material:

-

Silver steel contains a high percentage of carbon, typically around 1.0-1.2%, which allows it to be hardened to a high degree.

-

Despite its name, silver steel does not contain any silver. The name comes from its shiny, polished appearance.

-

This material is often used for making tools like drill bits, reamers, punches, and gauges due to its hardness and durability.

Composition and Properties

Understanding the composition and properties of silver steel helps in appreciating its applications and benefits.

-

Silver steel typically contains chromium, which enhances its wear resistance and toughness.

-

The material can be easily machined in its annealed state, making it a favorite among toolmakers.

-

When heat-treated, silver steel can achieve a hardness of up to 64 HRC (Rockwell Hardness Scale).

-

It has a tensile strength of approximately 700-850 MPa, making it strong and resilient.

Applications of Silver Steel

Silver steel's unique properties make it suitable for a wide range of applications.

-

It is commonly used in the manufacturing of cutting tools due to its ability to maintain a sharp edge.

-

Watchmakers use silver steel for making precision tools and components.

-

The material is also used in the production of measuring instruments like micrometers and calipers.

-

Silver steel is favored in the automotive industry for making parts that require high strength and wear resistance.

Advantages of Using Silver Steel

There are several advantages to using silver steel in various applications.

-

Its high carbon content allows for excellent hardening capabilities, making it suitable for high-stress applications.

-

The material's machinability in its annealed state reduces production time and costs.

-

Silver steel's ability to achieve a high polish makes it aesthetically pleasing for tools and instruments.

-

Its wear resistance ensures a longer lifespan for tools and components made from it.

Heat Treatment and Hardening

Heat treatment plays a crucial role in enhancing the properties of silver steel.

-

Silver steel can be hardened by heating it to a temperature of around 770-780°C and then quenching it in oil or water.

-

Tempering the material after hardening helps to reduce brittleness while maintaining hardness.

-

The tempering process involves heating the steel to a temperature between 150-300°C, depending on the desired hardness and toughness.

Historical Context

Silver steel has a rich history that dates back to the early 20th century.

-

The material was first developed in the UK and quickly gained popularity for its excellent properties.

-

It was initially used for making high-quality tools and instruments, which were in high demand during the industrial revolution.

-

Over the years, advancements in metallurgy have improved the quality and performance of silver steel.

Modern Uses and Innovations

Today, silver steel continues to be a valuable material in various industries.

-

It is used in the aerospace industry for making high-precision components.

-

The material is also utilized in the medical field for surgical instruments and implants.

-

Innovations in heat treatment and alloying have further enhanced the properties of silver steel, making it even more versatile.

-

With ongoing research and development, silver steel is expected to find new applications and continue to be a crucial material in manufacturing and engineering.

The Final Word on Silver Steel

Silver steel, also known as drill rod, stands out for its versatility and strength. This high-carbon steel is prized in tool-making and precision engineering. Its ability to be hardened and tempered makes it a favorite among machinists and hobbyists alike. Whether you're crafting custom tools or working on intricate projects, silver steel offers reliability and durability.

Understanding its properties, like its high carbon content and excellent wear resistance, can help you make informed decisions for your projects. Remember, proper handling and heat treatment are key to unlocking its full potential.

In short, silver steel is a go-to material for those needing a robust, adaptable metal. From DIY enthusiasts to professional engineers, its applications are vast and varied. So next time you need a dependable material, consider silver steel—it won't let you down.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.