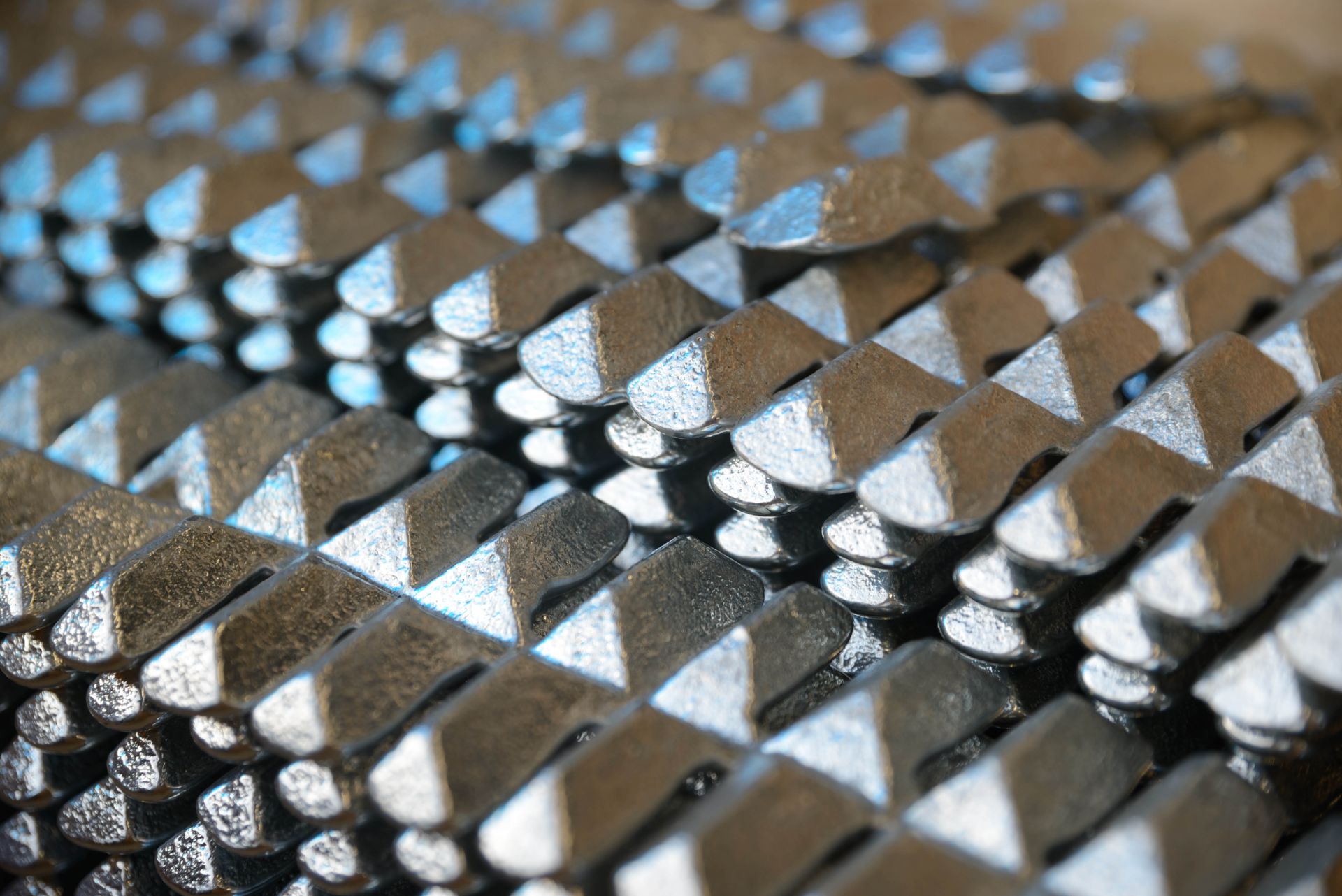

Zamak, a term you might not hear every day, plays a crucial role in many industries. But what exactly is Zamak? Zamak is a family of alloys with a base metal of zinc and alloying elements of aluminum, magnesium, and copper. Known for its excellent casting properties, Zamak is widely used in die-casting processes. Its name is derived from the German words for the metals it contains: Zink, Aluminium, MAgnesium, and Kupfer (copper). This versatile material offers high strength, durability, and resistance to corrosion, making it ideal for producing intricate and detailed components. From automotive parts to household items, Zamak's applications are vast and varied. Ready to learn more about this fascinating alloy? Let's dive into 40 intriguing facts about Zamak!

Key Takeaways:

- Zamak is a versatile alloy made of zinc, aluminum, magnesium, and copper. It's used in cars, electronics, and household items due to its strength, durability, and resistance to corrosion.

- Despite its strengths, Zamak has limitations like sensitivity to high temperatures and brittleness. However, innovations like high-purity versions and nano-coatings are improving its performance and sustainability.

What is Zamak?

Zamak is a family of alloys with a base metal of zinc and alloying elements of aluminum, magnesium, and copper. Known for its versatility, Zamak is used in various industries, including automotive, electronics, and household goods.

- Zamak stands for Zinc, Aluminum, Magnesium, and Kupfer (the German word for copper).

- Developed in the 1920s by the New Jersey Zinc Company, Zamak revolutionized metal casting.

- Zamak alloys are known for their excellent casting properties, making them ideal for intricate designs.

- These alloys are often used in die-casting due to their low melting point and high fluidity.

- Zamak is highly resistant to corrosion, which makes it suitable for outdoor applications.

Types of Zamak Alloys

There are several types of Zamak alloys, each with unique properties tailored for specific applications.

- Zamak 2 has the highest strength and hardness among Zamak alloys.

- Zamak 3 is the most commonly used alloy, offering a good balance of strength and ductility.

- Zamak 5 contains more copper than Zamak 3, providing better strength and hardness.

- Zamak 7 has lower magnesium content, resulting in better ductility and impact resistance.

- Zamak 8 is a high-purity alloy with excellent mechanical properties and corrosion resistance.

Applications of Zamak

Zamak's versatility makes it a popular choice in various industries, from automotive to consumer goods.

- Automotive parts like door handles, emblems, and carburetors often use Zamak for its durability.

- Electronics benefit from Zamak's excellent electrical conductivity and shielding properties.

- Household goods such as faucets, locks, and zippers are frequently made from Zamak.

- Toys and model kits often use Zamak for its ability to create detailed and durable parts.

- Jewelry and fashion accessories sometimes incorporate Zamak for its aesthetic appeal and ease of casting.

Advantages of Using Zamak

Zamak offers several benefits that make it a preferred material in many applications.

- Cost-effective: Zamak is relatively inexpensive compared to other metals like aluminum and brass.

- Recyclable: Zamak can be easily recycled, making it an environmentally friendly option.

- High precision: Zamak's excellent casting properties allow for the production of high-precision parts.

- Good surface finish: Zamak parts often require minimal finishing, reducing production costs.

- Dimensional stability: Zamak maintains its shape and size over time, ensuring long-lasting performance.

Challenges and Limitations

Despite its many advantages, Zamak also has some limitations that need to be considered.

- Temperature sensitivity: Zamak can lose strength at high temperatures, limiting its use in high-heat environments.

- Brittleness: While Zamak is strong, it can be brittle and prone to cracking under certain conditions.

- Weight: Zamak is heavier than some other materials like aluminum, which can be a drawback in weight-sensitive applications.

- Corrosion: Although resistant to corrosion, Zamak can still corrode if not properly coated or treated.

- Surface defects: Zamak can develop surface defects like blisters and porosity during casting.

Innovations in Zamak

Recent advancements have improved the performance and applications of Zamak alloys.

- High-purity Zamak: Newer high-purity versions offer better mechanical properties and corrosion resistance.

- Nano-coatings: Innovative coatings enhance Zamak's durability and resistance to wear and corrosion.

- Hybrid alloys: Combining Zamak with other materials can create alloys with unique properties tailored for specific applications.

- 3D printing: Advances in 3D printing technology allow for the creation of complex Zamak parts with high precision.

- Sustainability: Efforts to improve the recyclability and environmental impact of Zamak are ongoing.

Fun Facts About Zamak

Zamak has some interesting and lesser-known aspects that make it a fascinating material.

- Zamak coins: Some countries use Zamak to mint coins due to its durability and cost-effectiveness.

- Musical instruments: Certain musical instruments, like harmonicas, use Zamak for its acoustic properties.

- Art and sculpture: Artists sometimes use Zamak to create intricate sculptures and art pieces.

- Historical significance: Zamak played a crucial role in the development of the die-casting industry.

- Space applications: Zamak has been used in some space applications due to its unique properties.

Zamak in Everyday Life

You might be surprised to find Zamak in many everyday items you use.

- Kitchen appliances: Many kitchen gadgets and appliances contain Zamak parts for their durability and aesthetic appeal.

- Bathroom fixtures: Faucets, showerheads, and other bathroom fixtures often use Zamak for its corrosion resistance.

- Furniture hardware: Drawer pulls, knobs, and other furniture hardware are frequently made from Zamak.

- Sports equipment: Some sports equipment, like golf clubs and fishing reels, incorporate Zamak for its strength and precision.

- Fashion: Zamak is used in various fashion accessories, including belt buckles, buttons, and jewelry.

Zamak's Impact on Modern Manufacturing

Zamak alloys have revolutionized modern manufacturing. Their unique blend of zinc, aluminum, magnesium, and copper offers exceptional strength, durability, and versatility. These alloys are used in everything from automotive parts to household items, making them indispensable in various industries.

The cost-effectiveness and ease of production make Zamak a favorite among manufacturers. Its ability to be cast into intricate shapes without losing structural integrity is a game-changer. Plus, Zamak's resistance to corrosion ensures long-lasting products, reducing the need for frequent replacements.

Understanding Zamak's properties and applications helps appreciate its role in everyday life. Whether it's the zipper on your jacket or the components in your car, Zamak's presence is undeniable. This alloy's contribution to manufacturing efficiency and product longevity can't be overstated.

Frequently Asked Questions

Was this page helpful?

Our commitment to delivering trustworthy and engaging content is at the heart of what we do. Each fact on our site is contributed by real users like you, bringing a wealth of diverse insights and information. To ensure the highest standards of accuracy and reliability, our dedicated editors meticulously review each submission. This process guarantees that the facts we share are not only fascinating but also credible. Trust in our commitment to quality and authenticity as you explore and learn with us.